Overview

Overview

Our Facilities and Capabilities include:

- Corporate fabrication facility located in Markle, IN (108,000 sq. ft.)

- Paint and assembly facility located in Markle, IN (26,000 sq. ft.)

- CNC mill & lathe machining and large weldments located in Fort Wayne, IN (70,000 sq. ft.)

- Powder Coat Finishing

- Lasers with Loading Systems

- Hi-Definition and Conventional Systems

- High tonnage/big Press Brakes, Punch and Turret Presses

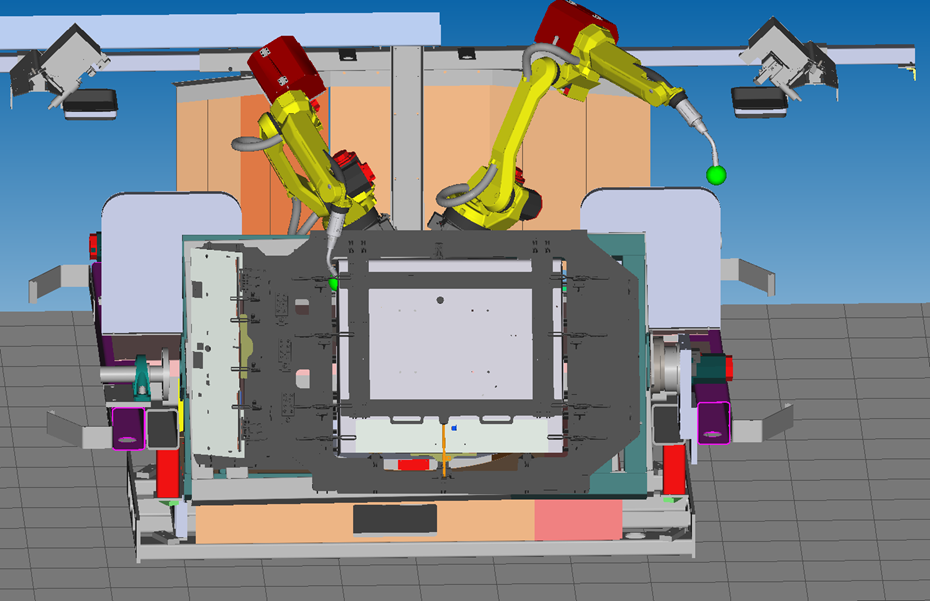

- Robotic Welding

- Assembly including hardware, gaskets, and foam insulation

- Just in time/Kanban delivery programs

- Aggressive Cost Reduction Activities

- CNC Mills and Lathes

Facility

Facility

- 18 acre Campus Markle Indiana

- 108,000 square feet of manufacturing space (Plant A)

- 26,000 square feet of paint system (Plant B)

- 70,000 square feet of manufacturing space (Plant C)

Engineering

Engineering

ENGINEERING/MANUFACTURING SOFTWARE

Visual Enterprise – Business software

CREO- 3D modeling software (with .iges, and .stp file capability)

AutoCad 2000 Software

Dr Abe- Press brake programming software

SmartCam – CNC Punching Software

SigmaNest – CNC Cutting/Nesting Software

TekSoft – DNC Networking Software

Ncell – Dynamic nesting software

Weld-Pro – Offline robot programming software

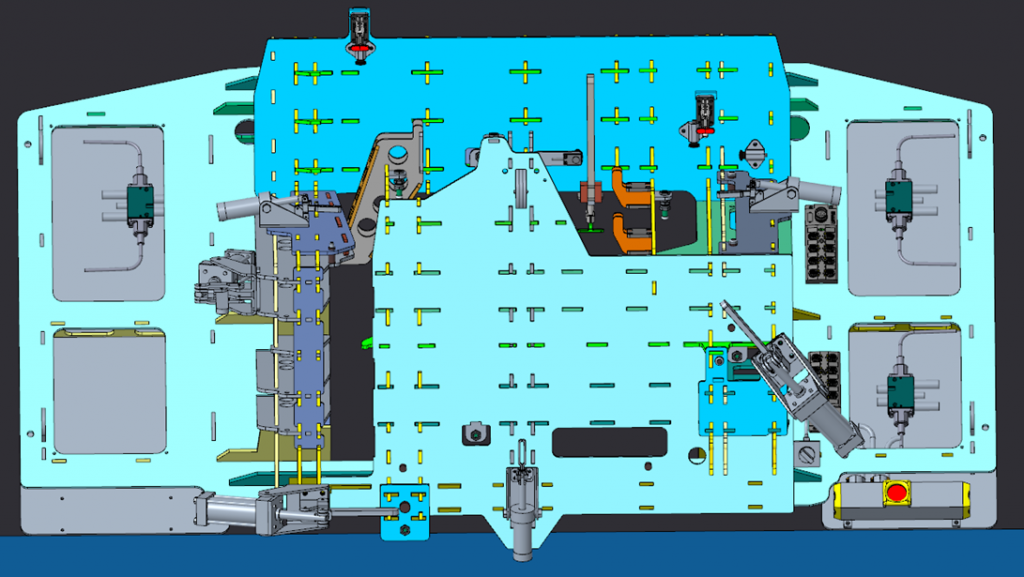

PTC Creo and Tooling Design

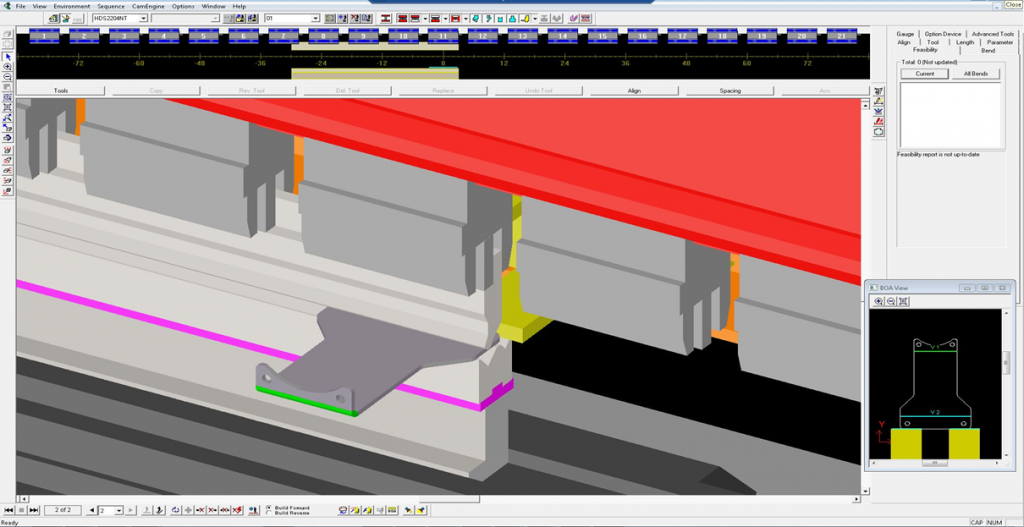

Dr.ABE Press Brake Offline Programming

WeldPro and Offline Programming

Inspection Equipment

Inspection Equipment

CMM

CMM Highlights

- Maximum drive speed 520 mm/s

- Measuring accuracy 1.7 µm*

- Maximum acceleration 0.23 g

- Integrated thermal-effect compensation for instrument and Workpiece in the temperature range 16 to 26 ºC

- High precision (resolution 0.1 µm), dustproof glass scales on all axes

- Self-adjusting air bearings on all axes

- Fully digitized servo control for low-vibration movements

- FEM-aided design ensures geometric accuracy and vibration resistance

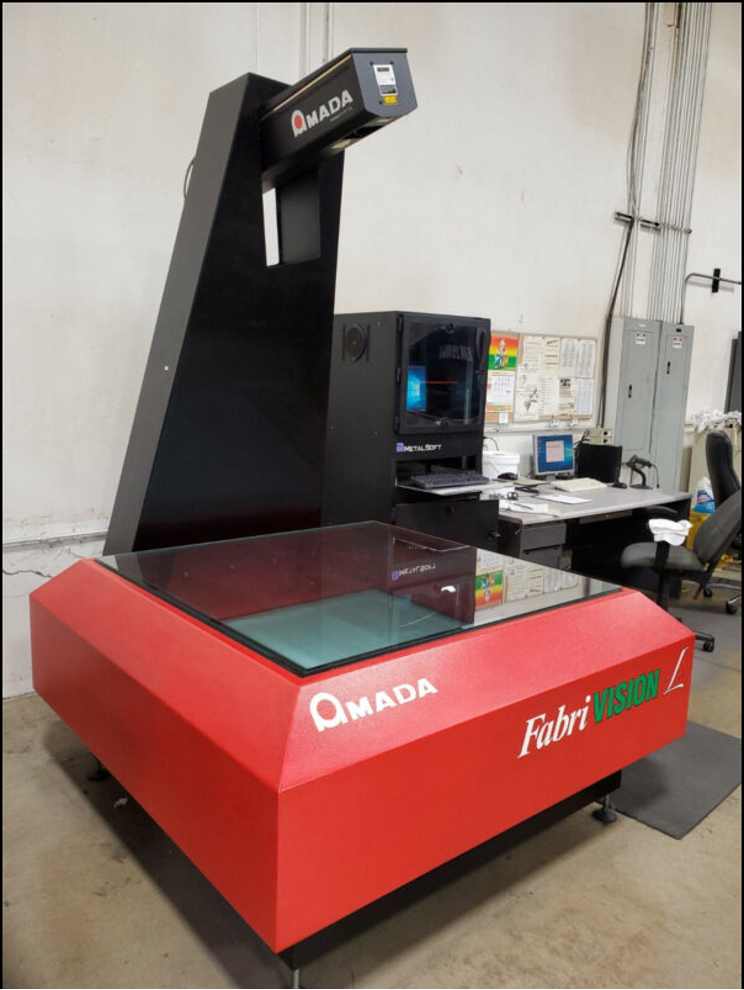

FabriVISION

Amada FabriVISION FVL-HD-4848 Scanning Sheet Metal Laser

- Visual Quality – SPC Stations located in every department

Mitutoyo – 123010 CMM CRYSTA-APEX C W/GEOPAK-MCOSMOS-3

Fabricating Equipment

Fabrication Equipment

Plasma

Laser

loading and sheet unloading capability

Turrets

Punch Presses

Punch Presses:

| Manufacture | Tonnage | Ram Size | Bed Size | Shut Height | Stroke | Air | Coil | Strokes/Min |

| Komatsu | 150 | |||||||

| Version | 150 | 34×30 | 50×30 | 23/18 | 6 | Y | 60 | |

| Blow | 400 | 84 L-R x 48 F-B | 84 L-R x 48 F-B | 26.75/17 | 12″ | Yes | Y | 20/50 |

| Niagara | 500 | 96 x 54 | 96 x 54 | 25.25/11.25 | 12″ | 3 | Y | 30 |

| Bliss | 200 | 72 x42 | 72 x 42 | 21.125/11.125 | 8″ | 1 | Y | 30 |

| Bliss | 200 | 38 x 28 | 58 x 34 | 18.8/15 | 8″ | 1 | Y | 35 |

| Danley | 250 | 48 x 36 | 48 x 36 | 31/19 | 12″ | 1 | Y | 30 |

| Sutherland | 440 | 122 x 55 | 122 x 55 | 32/22 | 10″ | — | Y | 20/40 |

Coil Feeder Specs:

Material Thickness .020” – .250” Coil Width .375” – 36”

Material Thickness .020” – .200” Coil Width .375” – 18”

Material Thickness .020” – .342” Coil Width 1.00” – 13”

Press Brakes

Pacific (3) 40-225 6’-12’ Auto back gauge and ram control

Cincinnati (1) 400 16’ Manual back gauge

Amada (4) 88-300 7’-8”-13’ Auto back gauge

Amada (4) 88-250 10’-14’ Auto back gauge, off-line programmable

Drills, Mills, Assembly

Robotic Welding

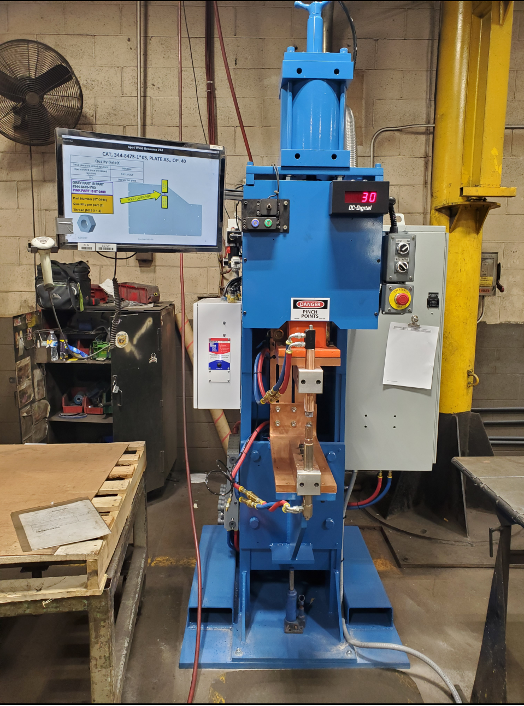

Spot Welding

Spot Weld (2) 200 KVA machines

(3) 150 KVA machines

(1) 100 KVA machines

Stud Weld Stud gun, 3-phase multi-stud capability

CNC Turning

Haas ST-10 (6’’Dia. 2’’ thru)

Haas SL-40 (25” Dia. 4” thru)

CNC Milling

Haas VM6 (32 x 64)

Haas VF4 (20 x 50) W/Pallet Changer